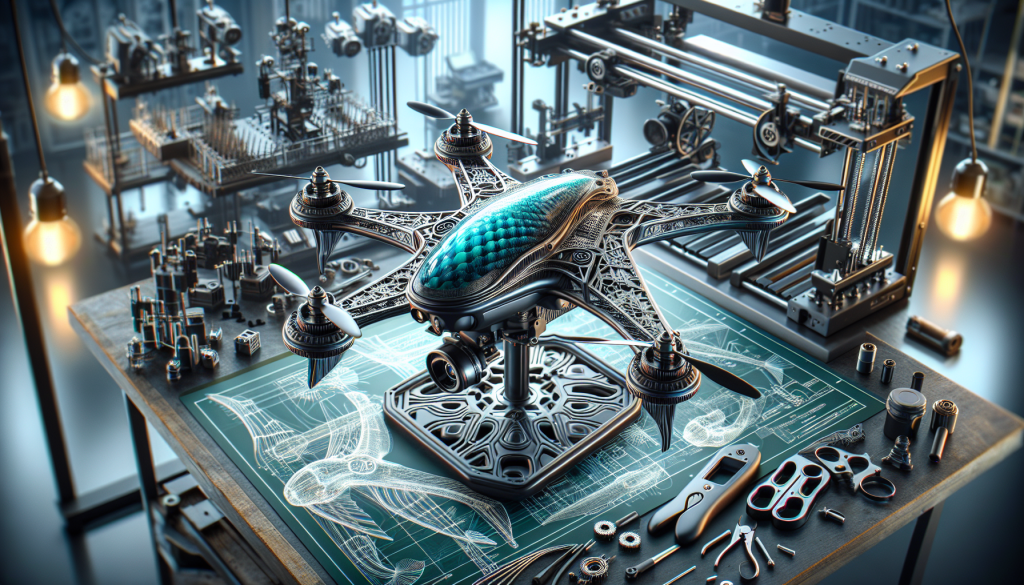

The Revolutionary HANX Drone: A Game-Changer for the Marine Corps

At an astonishingly low cost of around $700 for its base model, the HANX platform marks a significant milestone as the Marine Corps’ first 3D-printed drone. This innovation not only adheres to stringent laws prohibiting the U.S. military from acquiring unmanned aerial systems with foreign components but also opens the door to modern military applications that emphasize speed, affordability, and compliance with national security regulations.

Meet the Innovator: Sgt. Henry David Volpe

Leading this groundbreaking initiative is Marine Sgt. Henry David Volpe, an automotive maintenance technician stationed with the 2nd Marine Logistics Group at Camp Lejeune, North Carolina. Volpe’s hands-on experience with 3D printing was pivotal as he spearheaded the HANX drone’s development. His work embodies the proactive spirit of the II Marine Expeditionary Force Innovation Campus, where Marines collaborate to tackle “ground level” challenges through advanced technology.

“Anyone can create a cheap drone using non-approved parts,” Volpe stated in a recent press release. “However, finding compliant parts that do not harbor hidden vulnerabilities is a complex task.” The design and functionality of HANX aim to solve this dilemma by maintaining compliance with the National Defense Authorization Act (NDAA), ensuring that the drone’s components are free from foreign influence.

The Importance of Compliance

The U.S. military faces significant complications regarding the supply chain for unmanned aerial systems (UAS), especially concerning parts sourced from adversarial countries like China. Historically, many small drones constructed by Marines relied on readily available but potentially insecure Chinese components. The transformation toward domestic and compliant production emphasizes national security, as most drones cleared through official channels were found to have critical components sourced from foreign entities.

Lt. Col. Eric Flanagan, a spokesperson for the Marine Corps, takes pride in the precautions taken to ensure compliance. “These systems are rigorously vetted to ensure they are NDAA-compliant and do not contain critical components from covered foreign entities,” he remarked.

A New Paradigm in Military Technology

The innovative spirit behind the HANX drone reflects a broader trend in military technology—empowering junior troops to innovate and create. The military is beginning to embrace a culture where younger service members generate their own solutions, potentially redefining how technology is integrated into defense strategies. For example, Volpe was inspired by visiting Fort Campbell, Kentucky, where soldiers had developed their own drones. This inter-service rivalry pushed him to design a cost-effective alternative that would meet military demands without compromising on capabilities.

“I saw drones that had excellent features but came with a hefty price tag,” he noted. “I knew I could produce something far more affordable without sacrificing too many features.”

A Vision for the Future

The potential applications for the HANX drone are vast, with flexibility built into its design allowing for varied military tasks. With a payload capacity of one kilogram, it can be tailored for functions including explosive ordnance disposal and public affairs.

The Innovation Campus is keen to further explore this technology for offensive, logistics, and surveillance training. “This in-house manufacturing capability is integral to our strategy to equip all formations with a suitable mix of unmanned systems,” Flanagan explained.

The Marine Corps anticipates a significant investment in drone technology, planning to buy 10,000 first-person-view drones within the coming years. While the standard cost for these systems is set around $4,000 per unit, HANX’s production cost puts it well below that threshold, indicating a bright future for 3D-printed military tech.

Recognition and Accomplishment

Volpe’s contributions haven’t gone unnoticed; he is slated to receive the Navy and Marine Corps Commendation Medal for his groundbreaking work. Reflecting on his journey, he remarked, “I’ve been to college before, rebuilt engines, but this is mine. This is what I designed. This is what I made.” His pride encapsulates the essence of innovation—the thrill of creation and contribution to military advancement.

The HANX drone is not just a technological achievement but a symbol of creative adaptation and resilience within the military landscape. As the U.S. military continues to refine its approach to unmanned aerial systems, the spotlight on home-grown solutions like HANX will undoubtedly shift the way operations are conducted, enhancing readiness against evolving threats on the battlefield.